To properly port the upper manifold it must be cut open from the surge tank and welded back up when the porting is complete. Cutting open the surge tank isn’t entirely necessary… but it may help flow a little more air with some polishing. In doing so, I wanted to mimic the NGM and Neztec stage 3 manifolds for as little money as possible.

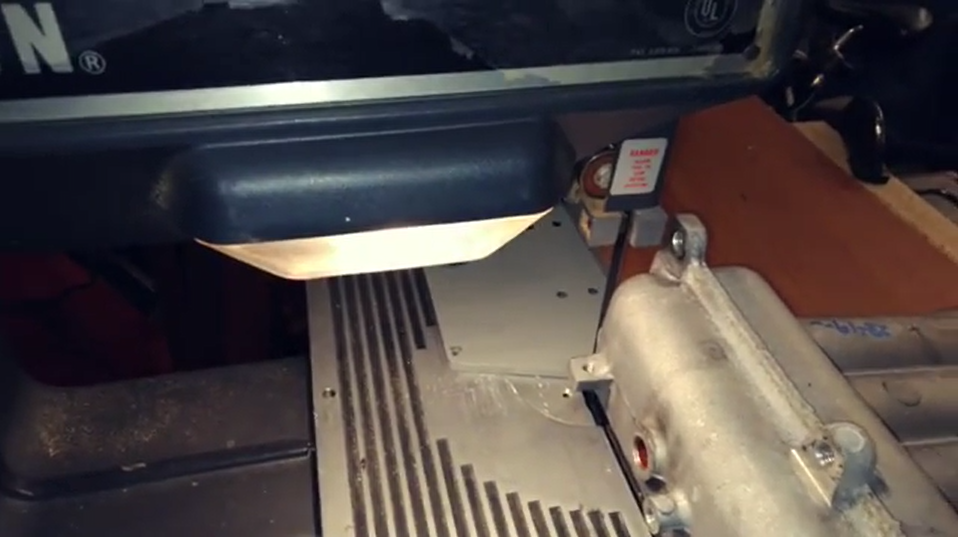

The only tools I had on hand to make a clean cut was a Craftsman wood band saw from the 70s. Thankfully there are blades to cut soft metals which are compatible with the wood saws for relatively cheap. I was very lucky with my first manifold and it came out perfect as you’ll see below… However, my second manifold was mangled badly by blade walk and won’t be recoverable.

To port the upper manifold I used all the same tools that I did with the lower, except I tried out a rough cylinder hone and wool flap wheels for polishing. These were the tools I used:

- Upright band saw with blade for soft metals

- Corded power drill. (Batteries don’t last long)

- 1/4″ extensions between 3-6″ long. Shorter the better for control and chatter.

https://www.amazon.com/gp/product/B07NBVGVPW - 1/4″ or 6mm shaft flap wheels. 40 and 120 grit. 1.5″ wide and 1″ wide

https://www.amazon.com/gp/product/B01M294IWS

https://www.amazon.com/gp/product/B01MQ1BIPI - Dremel with adjustable speed

- Dremel sanding drums of various sizes and grits

https://www.amazon.com/dp/product/B07CYQXZSY/ - Cylinder hone Size: 1-5/8″ & Grit Type: 120 https://www.amazon.com/gp/product/B002XUL0HW/

- Wool flap wheels in 1.5″ and 1″ wide https://www.amazon.com/gp/product/B07R14XK8K/

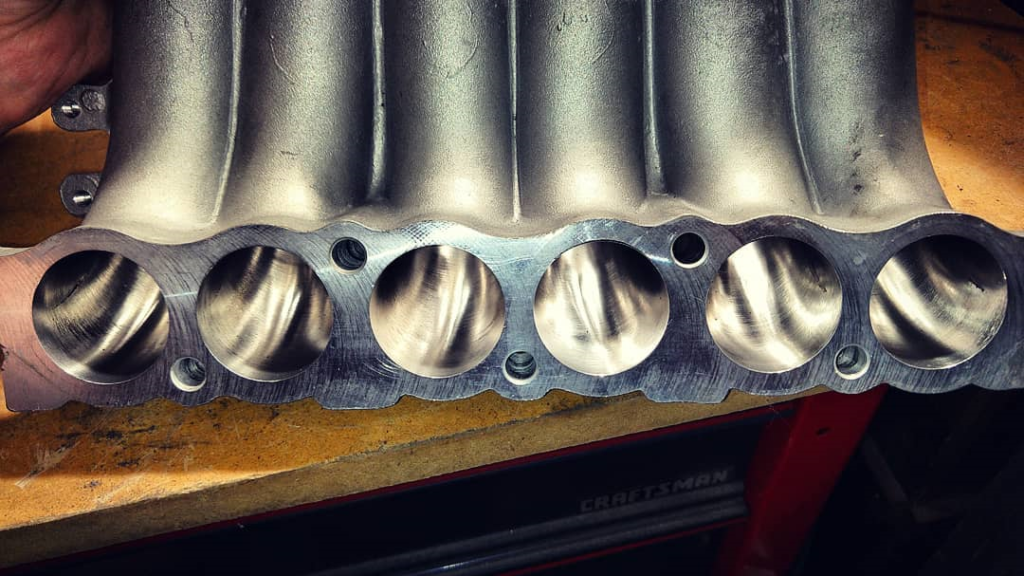

The biggest restriction of the OEM upper manifold is within 2-3 inches of the 90 degree bend into the lower manifold. This can be ported without cutting open the surge tank and in fact most of the gains can be found here:

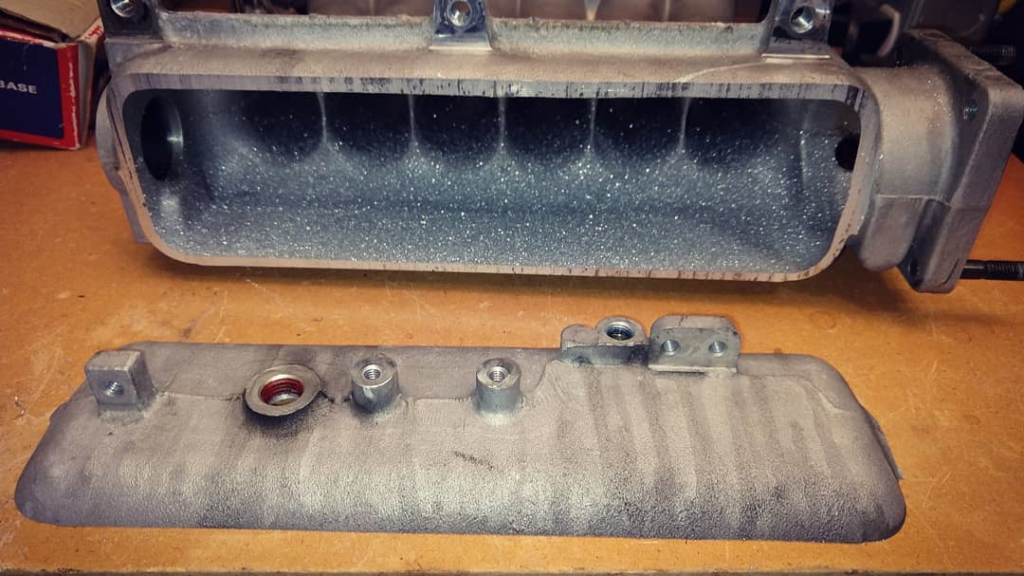

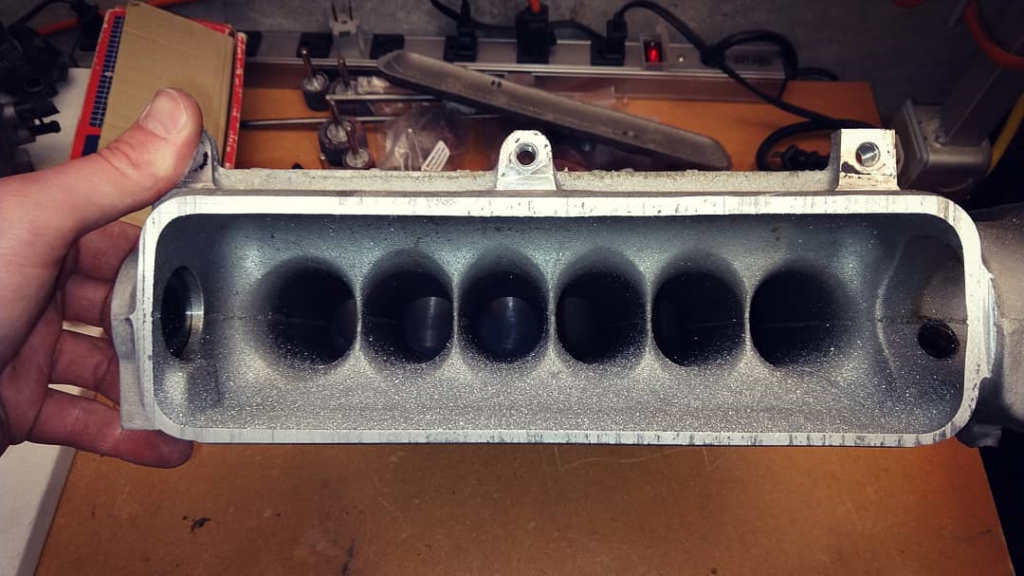

Porting out from the surge tank side is a little overkill since the average diameter of the oval ports is already ~40mm. Most of my time spent in the straight portion of the runners was to smooth out the bumps, clean up casting marks and polish all surfaces. The walls are way too thin between each runner to port it out aggressively and I’m not confident this area will see much for gains:

To do:

- Weld surge tank

- Ceramic coating